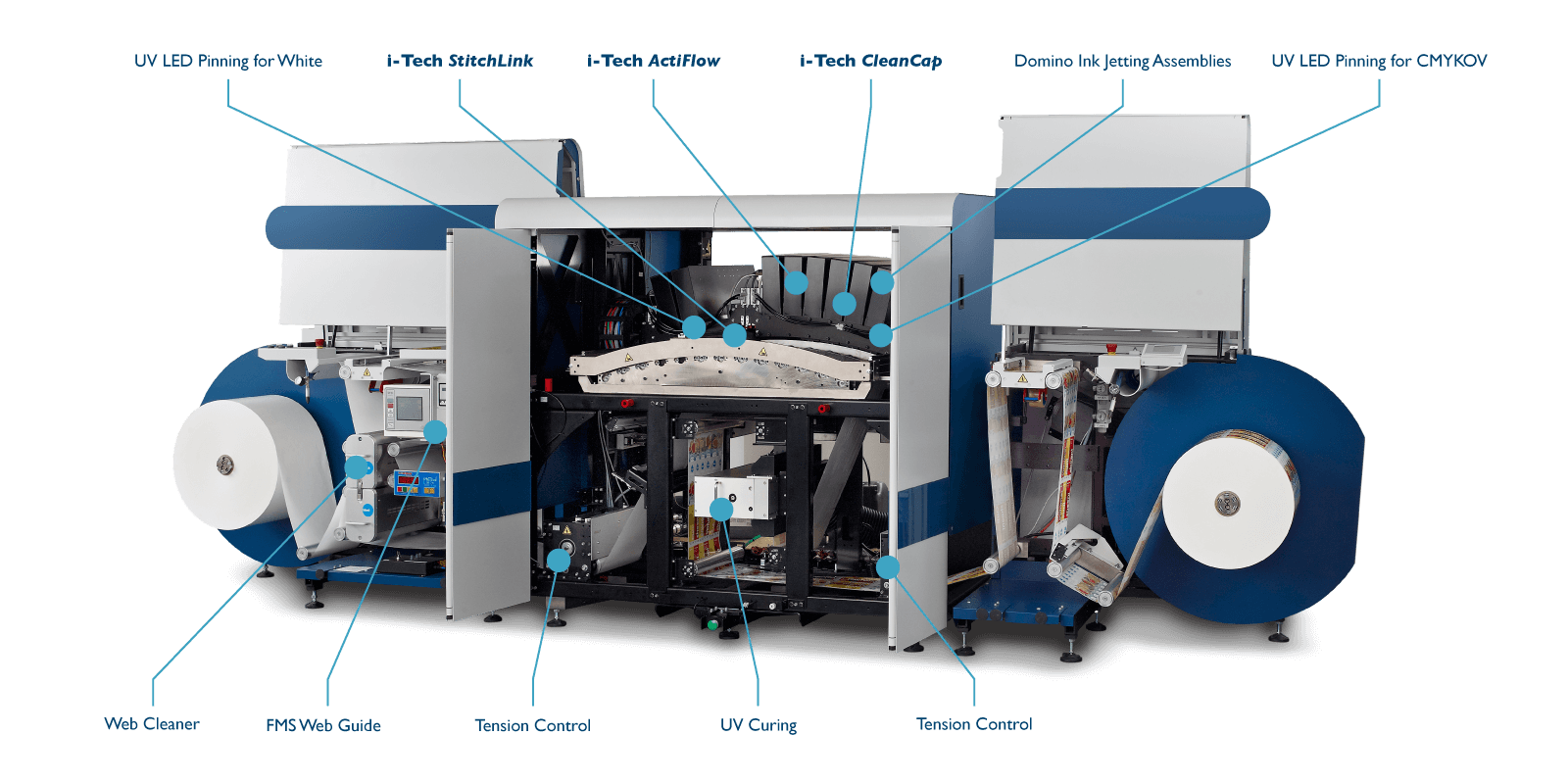

The industry standard seven colour 600dpi press

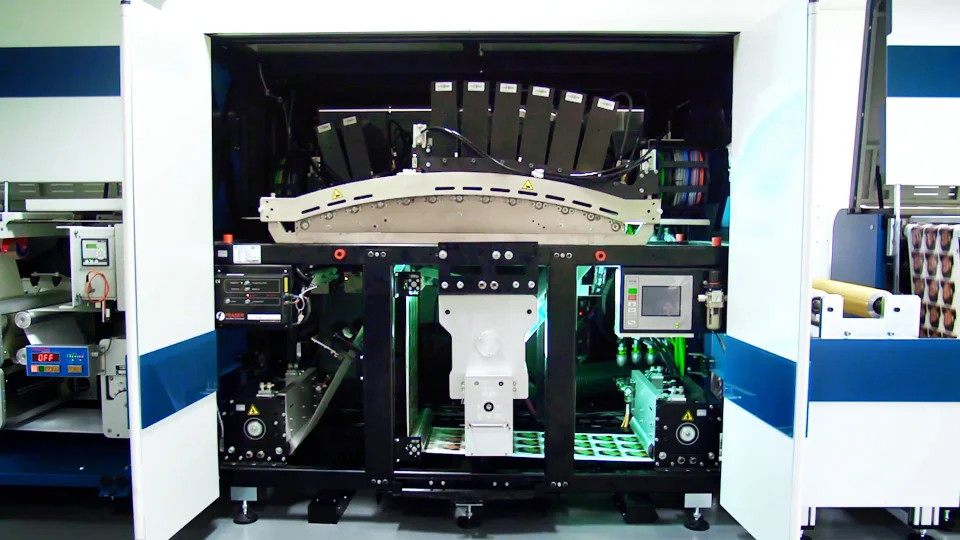

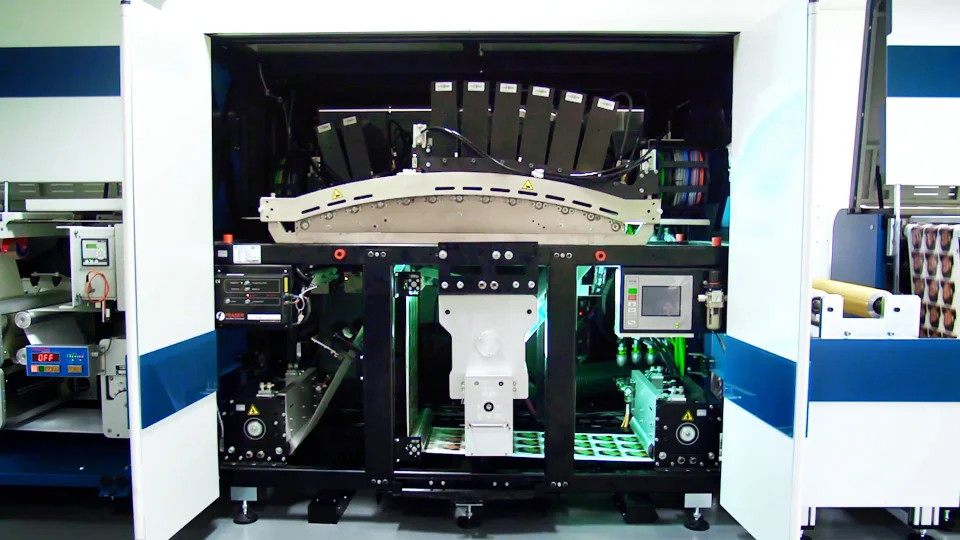

Based on Domino’s renowned Generation 6 technology, with approaching 1,000 global installations, the N610i 600dpi label press is the most proven inkjet solution for printing self-adhesive labels.

Configured as either reel-to-reel for the ultimate in flexibility; with priming for greater substrate support; with in-line finishing, or ideal for multiple SKU jobs as a full hybrid press integrated into any leading flexo press line.

The simple reel-to-reel 600dpi digital label press is ideal for the highest digital throughput, for the widest variety of jobs, including those that may need long finishing set-up times.

Domino’s Intelligent Technology features including i-Tech CleanCap, ActiFlow, StitchLink, WebRev and UltraMix combine to provide unparalleled reliability, automation and performance.

Industry standard ESKO Digital Front End and JDF/JMF support for a streamlined workflow integration. Improve efficiency, use, function and general performance for increased output and financial return with N610i 600dpi press investment.

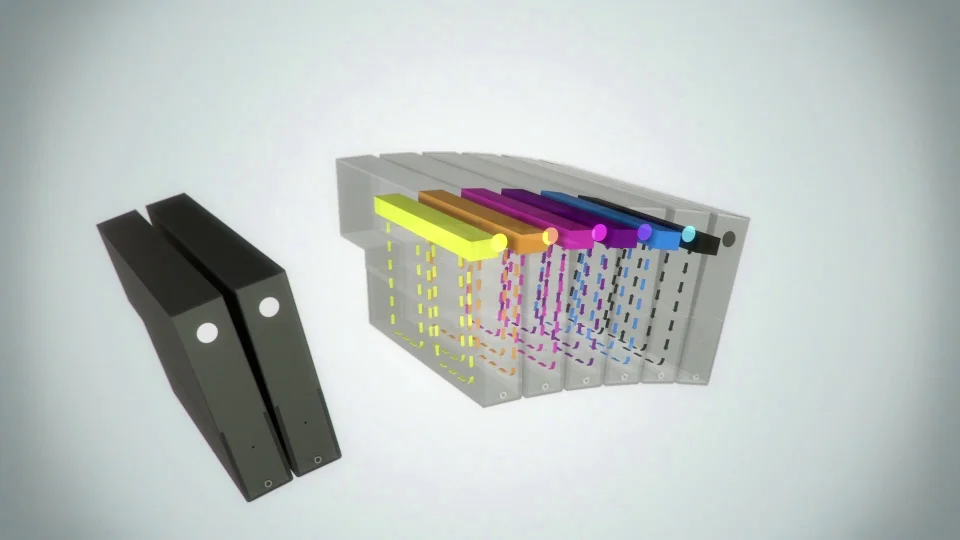

The Domino UV90 and UV95 ink sets provide excellent resistance to heat, cold, sunlight, chemical and saline attack as well as abrasion to maintain the highest quality through the life of the final product. The high opacity white is often used as a replacement for silk-screen printing.

A range of flexible purchase options exist for the N610i 600dpi digital label press, including our own in-house leasing option incorporating our all inclusive TotalCare plus maintenance and breakdown service programme.

Domino offers customers support with a wide range of services through its Digital Solutions Programme including how to sell digital, workflow integration and efficiency to advanced operator training.

Looking for more dpi?

Here's a digital label press with 1200dpi resolution

Exceptional inkjet quality, more resolution

Discover our market leading N610i digital label press

"Within just one month of installation, we had improved our lead times and quality, reduced our running costs, and we were already printing 25% of our turnover on the Domino press."

Ian Woodhead, Managing Director at Anglia Labels

-

All

-

Case Study

-

Product

N610i @Germark - The operator advantages

"The N610i's high productivity in m/min, very fast and constant. The maintenance which is very simple, fast and efficient, with no downtime. And the ink adhesion on the substrates is extremely good compared to other printing systems."

N610i @Germark - Silk-screen replacement

"With the Domno N610i the white is very opaque. The combination of the white and vibrant colours allows us to transfer designs from screen printing to ink jet."

Labelexpo Americas 2024 - N610i and N730i demo

Domino Demo Room Technician, Julie Krueger, presents live at Labelexpo Americas 2024 our N610i and N730i digital label presses. Revisit the demo and learn about the performance-enhancing features of our N-Series presses in this video.

N610i success story @Germark

Discover how Domino’s high opacity white ink has enabled Germark to replace conventional silk-screen jobs with inkjet technology

N610i @Anglia Labels: Domino's exceptional service

"We have been extremely impressed with the exceptional service provided by the whole Domino team" says Ian Woodhead, MD at Anglia Labels.

N610i @Anglia Labels: printing 25% of turnover within 1 month!

Just one month after installation, Anglia Labels is already printing 25% of their turnover on the Domino N610i inkjet label press!

Discover the Domino N610i label press

Highest digital productivity, most consistent print results, best digital inkjet quality - find out how Domino’s 7-colour N610i Digital Label Press can benefit your business.

N610i roll to roll with UV95 ink

Watch a demonstration of Domino's robust and reliable UV95 ink set on Domino’s market leading N610i digital inkjet label press.

Domino Digital Solutions Programme

The goal of the program is to make our customers as productive, as possible as quickly as possible…helping them achieve: top-line growth, lower costs, less risk, less downtime and more uptime.

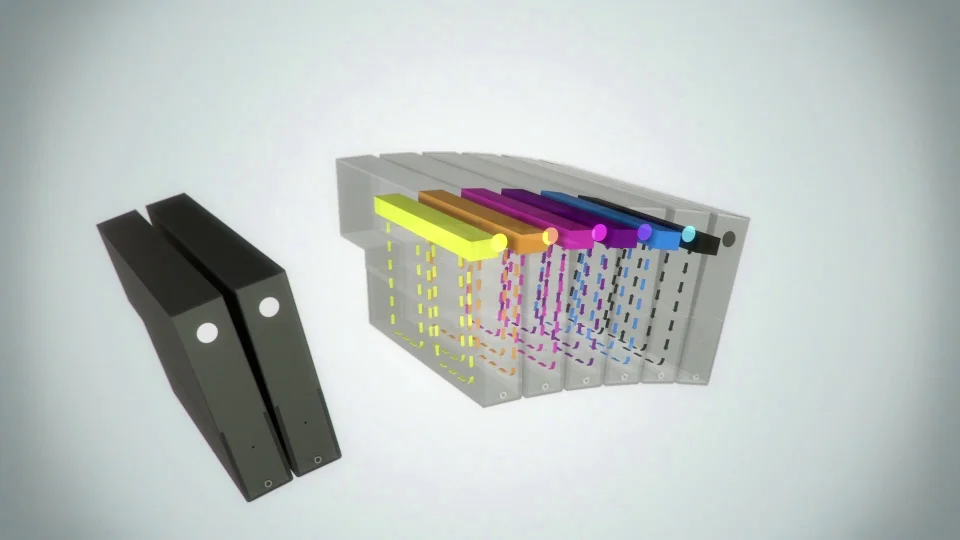

Domino N610i i-Tech Actiflow

The ActiFlow ink circulation system keeps the ink continuously moving around the print head, maintaining a constant temperature and removing micro air bubbles, ensuring consistent print quality and reliability..

Domino N610i i-Tech CleanCap

The CleanCap automated print head cleaning and capping station ensures the highest print quality and productivity – all heads are cleaned within one minute!

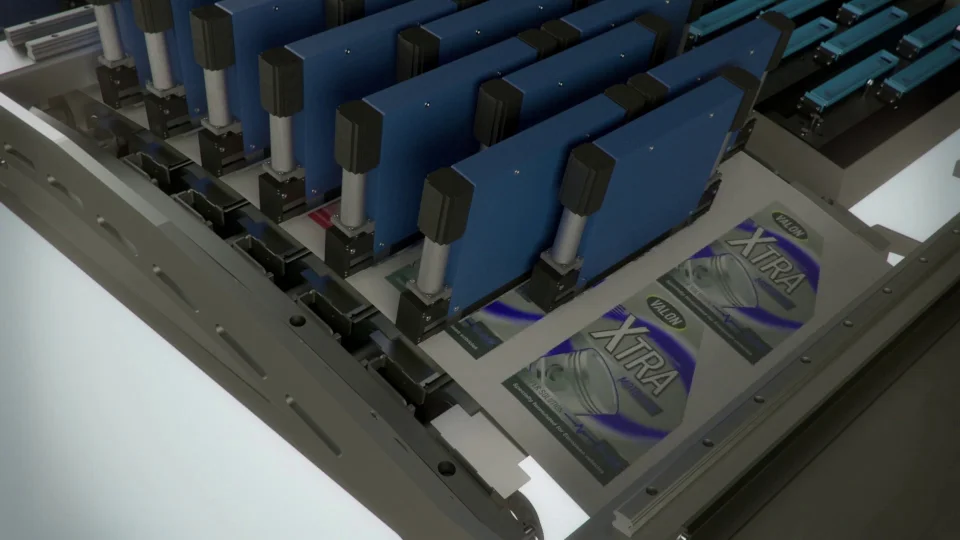

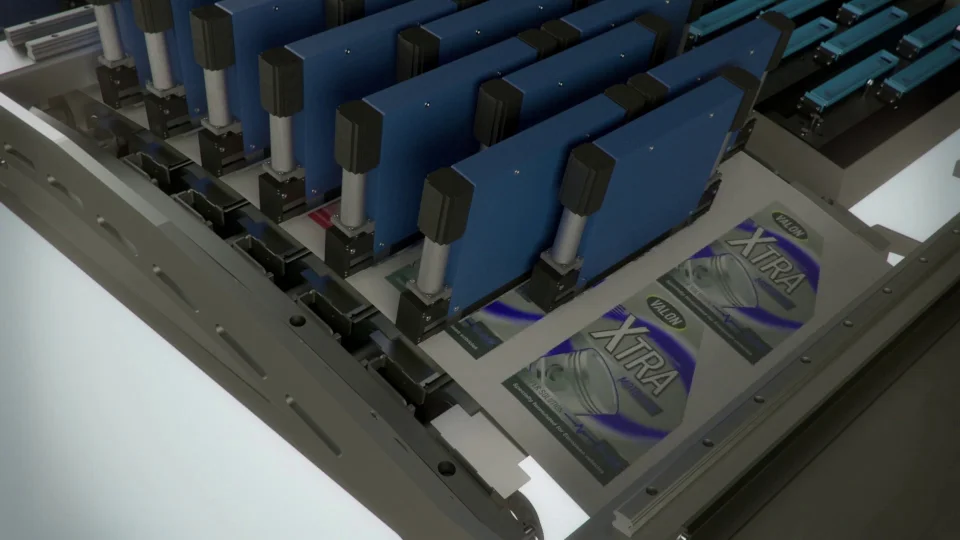

Domino N610i i-Tech StitchLink

The StitchLink micro-motor controller technology ensures that all heads are positioned precisely, calibrated to print as one, enabling seamless print across the full web width.

N610i @Multi Packaging Solutions Bristol

"We found that within the eight weeks of Domino press going live we actually brought on forty new customers"

Domino In-House Leasing Programme

Domino's Leasing Program allows your business to grow with advancements that are made in digital technology. Watch the video to learn more!

N610i @Germark - The operator advantages

"The N610i's high productivity in m/min, very fast and constant. The maintenance which is very simple, fast and efficient, with no downtime. And the ink adhesion on the substrates is extremely good compared to other printing systems."

N610i @Germark - Silk-screen replacement

"With the Domno N610i the white is very opaque. The combination of the white and vibrant colours allows us to transfer designs from screen printing to ink jet."

N610i success story @Germark

Discover how Domino’s high opacity white ink has enabled Germark to replace conventional silk-screen jobs with inkjet technology

N610i @Anglia Labels: Domino's exceptional service

"We have been extremely impressed with the exceptional service provided by the whole Domino team" says Ian Woodhead, MD at Anglia Labels.

N610i @Anglia Labels: printing 25% of turnover within 1 month!

Just one month after installation, Anglia Labels is already printing 25% of their turnover on the Domino N610i inkjet label press!

N610i @Multi Packaging Solutions Bristol

"We found that within the eight weeks of Domino press going live we actually brought on forty new customers"

Labelexpo Americas 2024 - N610i and N730i demo

Domino Demo Room Technician, Julie Krueger, presents live at Labelexpo Americas 2024 our N610i and N730i digital label presses. Revisit the demo and learn about the performance-enhancing features of our N-Series presses in this video.

Discover the Domino N610i label press

Highest digital productivity, most consistent print results, best digital inkjet quality - find out how Domino’s 7-colour N610i Digital Label Press can benefit your business.

N610i roll to roll with UV95 ink

Watch a demonstration of Domino's robust and reliable UV95 ink set on Domino’s market leading N610i digital inkjet label press.

Domino Digital Solutions Programme

The goal of the program is to make our customers as productive, as possible as quickly as possible…helping them achieve: top-line growth, lower costs, less risk, less downtime and more uptime.

Domino N610i i-Tech Actiflow

The ActiFlow ink circulation system keeps the ink continuously moving around the print head, maintaining a constant temperature and removing micro air bubbles, ensuring consistent print quality and reliability.

Domino N610i i-Tech CleanCap

The CleanCap automated print head cleaning and capping station ensures the highest print quality and productivity – all heads are cleaned within one minute!

Domino N610i i-Tech StitchLink

The StitchLink micro-motor controller technology ensures that all heads are positioned precisely, calibrated to print as one, enabling seamless print across the full web width.

Domino In-House Leasing Programme

Domino's Leasing Program allows your business to grow with advancements that are made in digital technology. Watch the video to learn more!

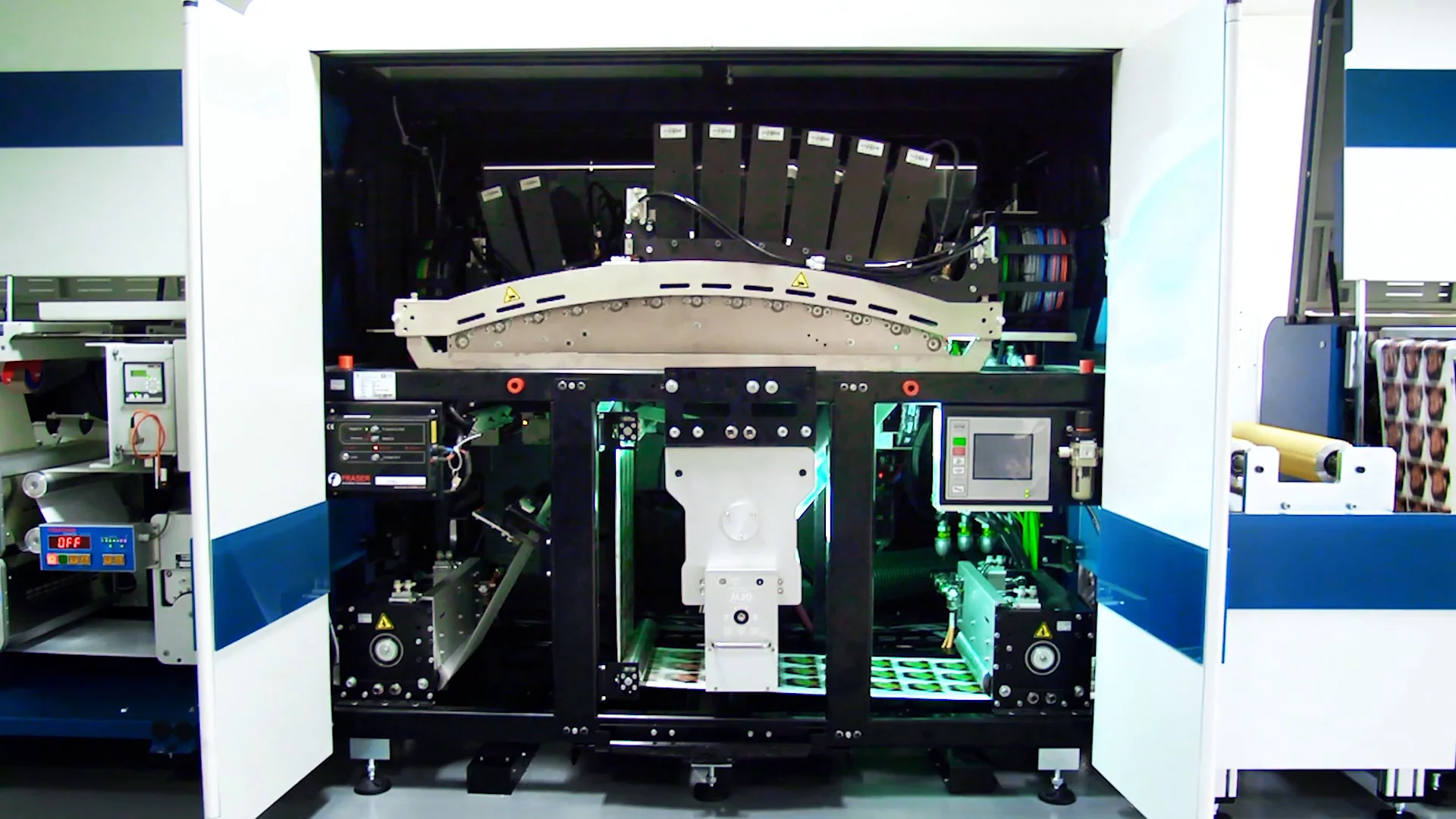

Take a closer look inside

Downloads

⬇ Domino N610i Brochure 2024 WEB (6.92MB)

⬇ Anglia Labels N610i Case Study (1.11MB)

⬇ Karico N610i Case Study (766KB)

⬇ ASQ N610i Case Study (957KB)

CONTACT US

Please complete the following (fields marked * are required)