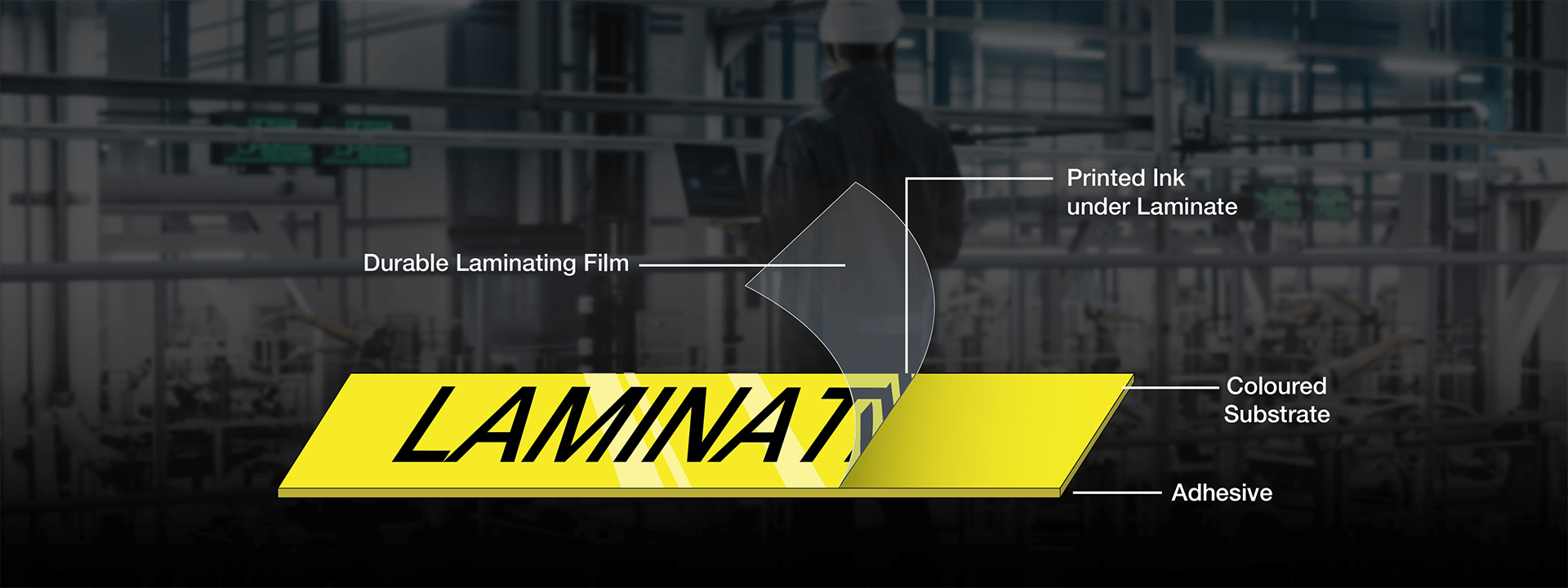

Enhance Your Operations with Brother's Auto-Lamination Technology

In the demanding environment of modern factories, the durability and clarity of labels are paramount. Brother's auto-lamination technology stands out as a revolutionary solution designed to meet these needs. This unique technology incorporates a sophisticated lamination process that ensures labels withstand the harshest conditions while maintaining their integrity and legibility.

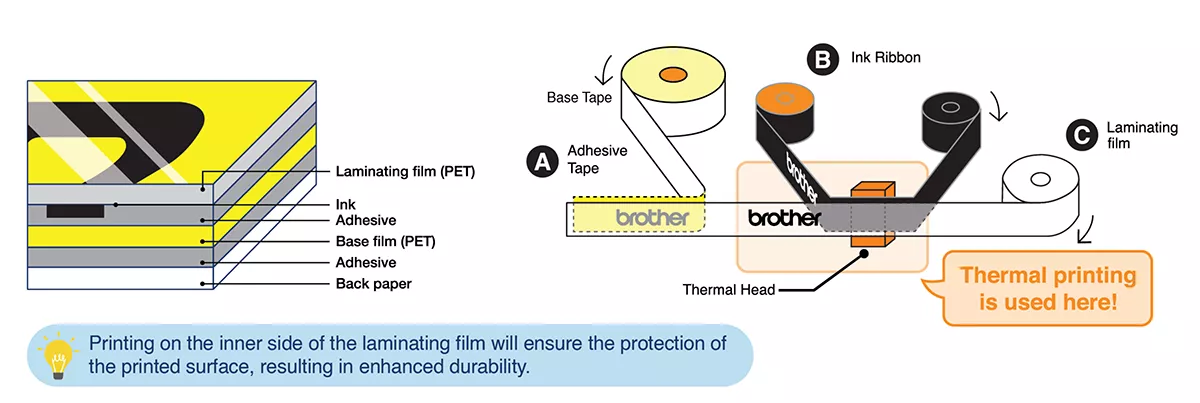

What is Auto-Lamination Technology?

Our TZe laminated tapes, a hallmark of Brother's innovation, consist of six meticulously engineered layers. This multi-layered construction results in labels that are both thin and extraordinarily strong. At the core of our TZe tapes is a layer of thermal transfer ink, which forms the characters on the label. This ink layer is expertly sandwiched between two protective layers of PET (Polyethylene terephthalate), providing unmatched protection.

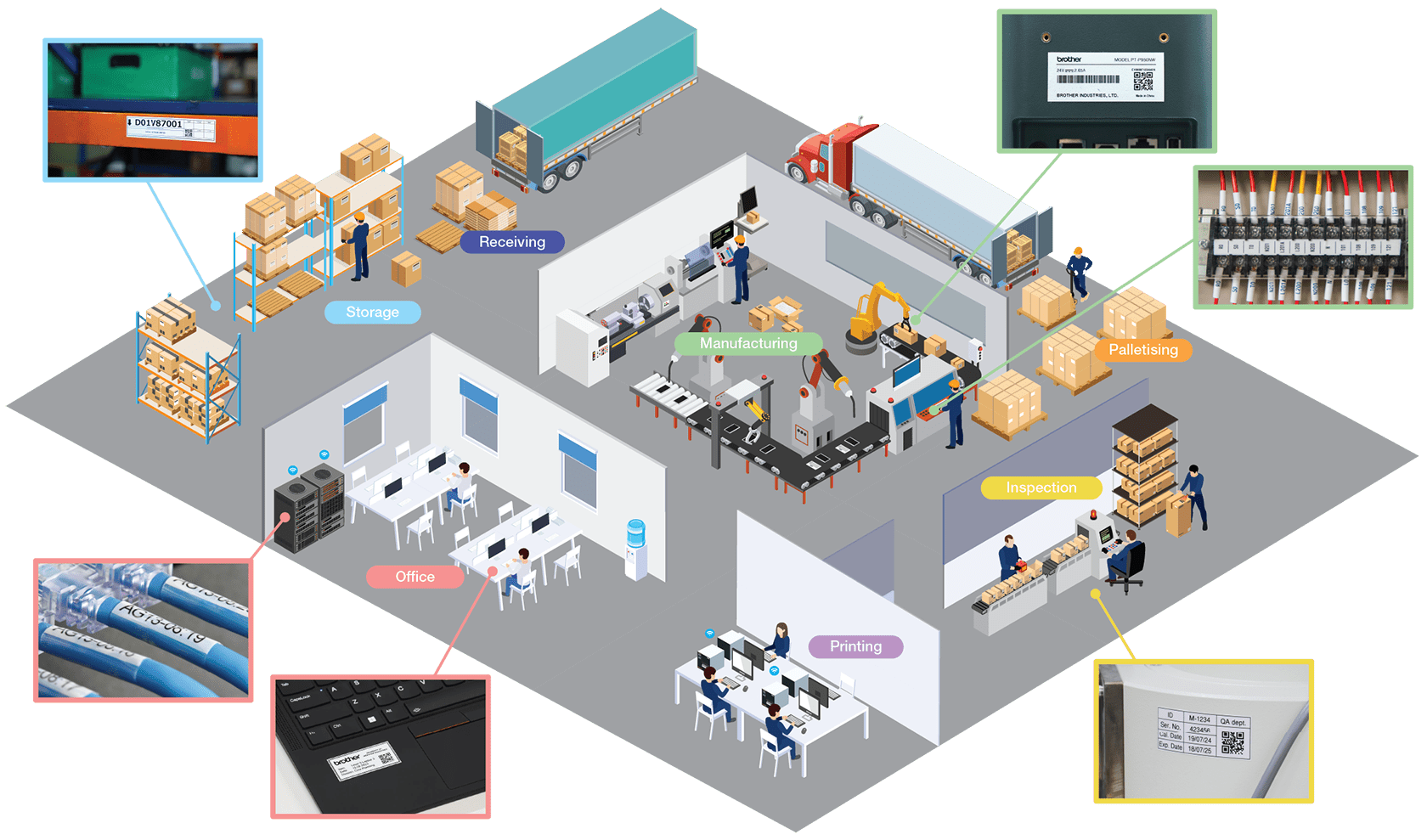

Versatile Applications in your factory

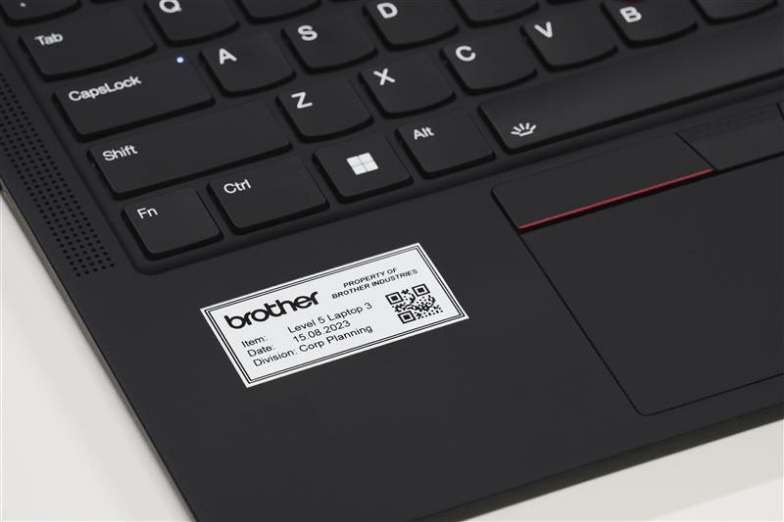

Office

Asset Management

5S

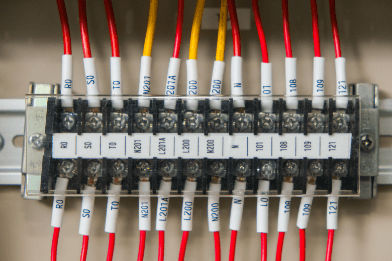

Cable Marking

Storage

Location Label

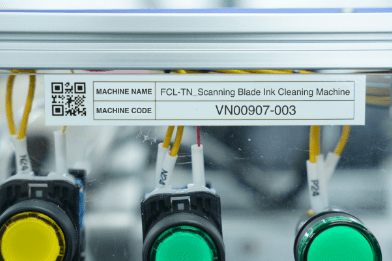

Manufacturing

Rating Label

Tool Management

Control Panel Marking

Asset Management Label

Instruction Label

Warning Label

Parts Management Label

Inspection

Calibration Label

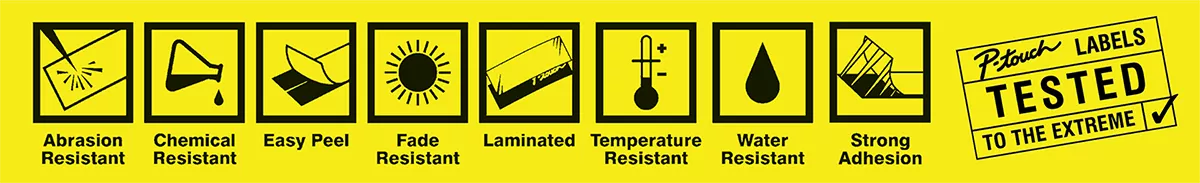

Unmatched Protection for Maximum Efficiency

The advanced construction of TZe tapes ensures that the labels are resistant to a variety of industrial challenges.

| Liquids: | Impervious to water, oils and other liquids, ensuring labels remain intact and legible. |

|---|---|

| Abrasion: | The PET layers safeguard against physical wear and tear, maintaining the label's clarity over time. |

| Temperature: | Capable of withstanding extreme temperatures, our labels remain stable in both hot and cold environments. |

| Chemicals: | Resistant to many chemicals, these labels are ideal for environments where exposure to harsh substances is common. |

| Sunlight: | UV-resistant properties protect labels from fading, ensuring they remain readable even with prolonged exposure to sunlight. |