The Importance of Traceability Labels in Factory Settings

In today's fast-paced manufacturing environments, the ability to track and trace products through every stage of production is crucial. Traceability labels play a vital role in ensuring quality control, regulatory compliance, and efficient supply chain management. They allow factory managers to pinpoint the origin of any issues, ensure product authenticity, and maintain detailed records of production batches.

Why Traceability is Essential

Quality Control:

Traceability helps monitor every stage of production, quickly identifying and isolating defects to ensure only high-quality products reach the market.

Regulatory Compliance:

Many industries require detailed production records. Traceability labels can help to meet these regulations by providing a clear history of each product.

Recall Management:

In case of a recall, traceability allows quick identification and removal of the affected batches, protecting the consumers and minimising the financial impact.

Brother's Affordable and Easy Label Solutions for Traceability

Brother offers innovative and cost-effective solutions to meet the traceability needs of factories. These solutions include Print from PLC and Scan to Print options, catering to different operational requirements.

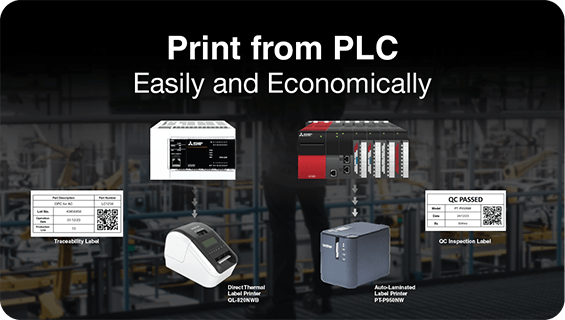

Print from PLC

For factories that utilise data directly from Programmable Logic Controllers (PLCs), Brother's Print from PLC solution is ideal. This method allows seamless integration with existing PLC systems, enabling automatic label printing directly from the PLC.

This ensures real-time updates and accurate labelling without manual intervention. Brother provides a Mitsubishi Electric PLC sample program and manual for free, making it easier for factories to implement this solution. The integration is straightforward, and Brother's support ensures a smooth transition.

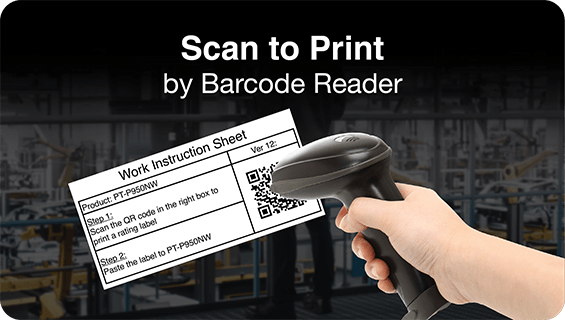

Scan to Print

For operations that rely on data from barcodes, Brother's Scan to Print solution is a more economical and user-friendly option. This method allows workers to scan barcodes and print labels instantly, streamlining the process and reducing errors.

The simplicity of Scan to Print makes it accessible for various factory setups, enhancing efficiency without significant investment in new systems.

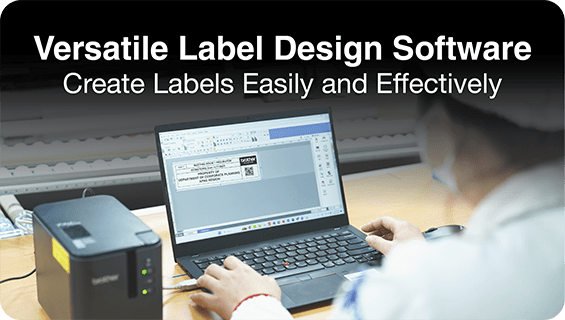

User-Friendly Label Design Software

Creating custom labels has never been easier with Brother's free label design software. This software provides an intuitive interface that allows users to design labels to meet specific requirements, whether for traceability, compliance, or branding. The ease of use ensures that even those with minimal technical skills can produce professional-quality labels.

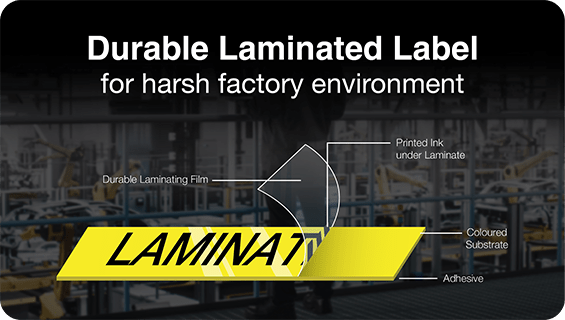

Durability in Harsh Environments

In many factory settings, labels must withstand harsh conditions, including exposure to chemicals, extreme temperatures, and abrasion. Brother's laminated labels are designed to meet these challenges. These labels feature two PET (polyethylene terephthalate) layers that sandwich the ink ribbon, providing exceptional durability.

These laminated labels are ideal for long-term traceability, ensuring that information remains legible and intact throughout the product's lifecycle. This robustness makes Brother's labels a reliable choice for industries where label integrity is paramount.

Conclusion

Traceability labels are essential for maintaining quality and efficiency in factory operations. Brother's solutions, including Print from PLC and Scan to Print, offer versatile and affordable options to meet various traceability needs. With free resources such as the Mitsubishi Electric PLC sample program, easy-to-use label design software, and durable laminated labels, Brother ensures that factories can implement effective traceability systems with minimal hassle and maximum reliability.

By choosing Brother, factories can enhance their traceability processes, ensuring accurate and durable labelling that stands up to the rigours of industrial environments.