Automating Factory Labelling with Brother's PLC Integration

In factory settings, efficiency and precision are crucial, especially when it comes to label printing. Integrating Brother’s printing solutions with PLCs (Programmable Logic Controllers) enables in-line label printing, streamlining the process and significantly reducing labour costs associated with printing, sorting, and distributing labels. This integration also allows for the automation of manual labelling tasks, enhancing overall productivity and operational efficiency.

Common Issues in Label Printing from PLC

Time-Consuming Label Design Creation:

Creating labels from scratch can be time-consuming, especially if the user interface is unfamiliar or if programming is required.

Expensive Initial Cost:

The initial cost of purchasing label printers, software, and PCs can be high, making it a significant investment.

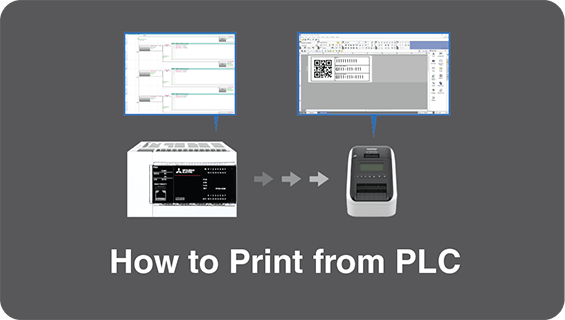

Brother's PLC Printing Solution

Brother addresses these common issues with their PLC integration, providing a simple and efficient way to print labels.

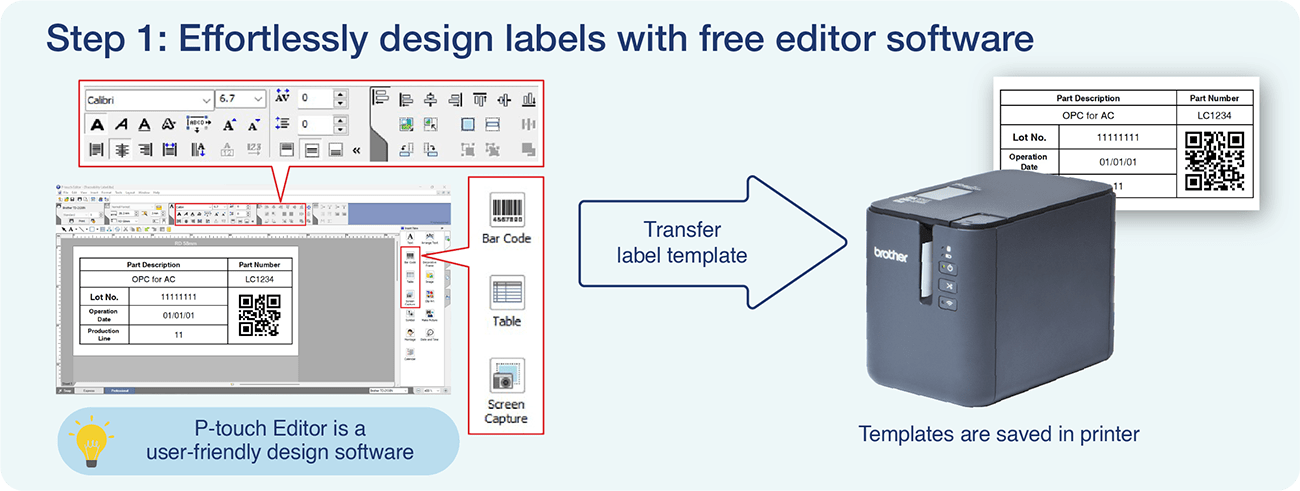

Easy-to-Use Label Design Software:

Brother’s P-touch Editor software is provided free of charge, making it easy to create custom labels quickly and saving time on label design creation.

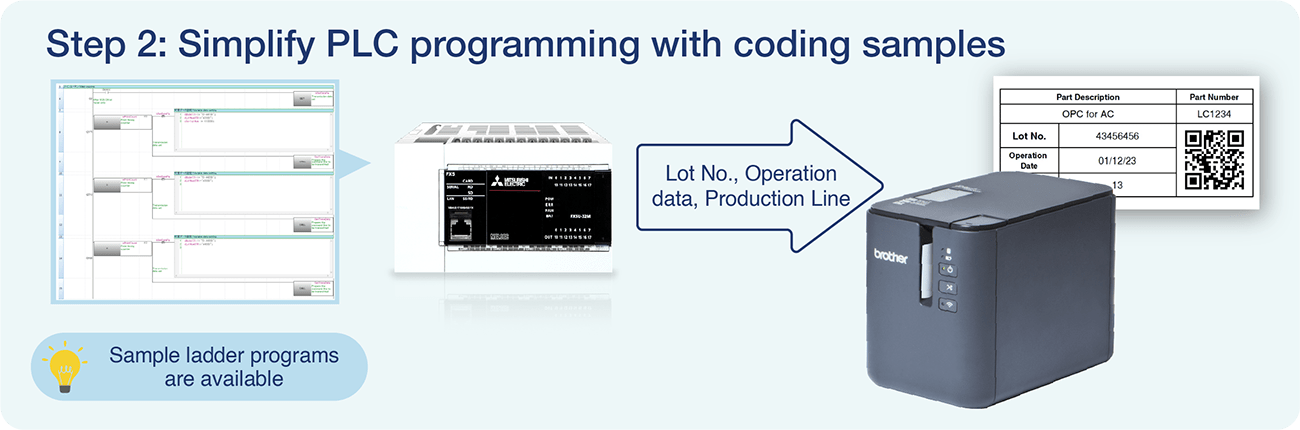

Sample PLC Programs Available:

Brother provides sample PLC programs along with manuals, significantly reducing the time and effort required for coding and integration.

Steps to Set Up PLC Printing

(Detailed procedure is here)

1. Download Sample Program:

Download the sample program for your PLC from Brother Solutions Center.

2. Create and Save Label Design:

Open the sample .lbx file with P-touch Editor, set your label printer model, and save the label design file.

3. Send the Label File to Label Printer:

Send the label design file to the label printer to ensure it is correctly formatted and compatible.

4. Customise the PLC Program:

Refer to the manual and customise the sample PLC program to include the necessary commands for sending data to the label printer.